To maintain your booster pump, regularly inspect for unusual noises, leaks, and electrical issues, and clean its parts like impellers and casings to prevent buildup. Monitor water pressure and flow to catch problems early, and check filters frequently for blockages. Lubricate moving parts as recommended, and test valves and pressure switches for proper operation. If problems persist, scheduling professional maintenance can prevent major failures—continue with this guide to learn more about keeping your pump in top shape.

Key Takeaways

- Regularly inspect and clean pump components, including impellers and seals, to prevent buildup and ensure optimal performance.

- Monitor water pressure and flow rates, and check filters frequently to detect blockages or system inefficiencies.

- Listen for unusual noises or vibrations that may indicate cavitation, bearing wear, or misalignment, and address issues promptly.

- Inspect electrical wiring and connections for corrosion, damage, or looseness to maintain safety and reliable operation.

- Schedule professional maintenance and inspections periodically to identify hidden problems and ensure system longevity.

Understanding Your Booster Pump System

Understanding your booster pump system is essential for proper maintenance and reliable operation. One key aspect is being aware of pump noise, which can indicate issues like cavitation or bearing wear. Unusual sounds should never be ignored, as they may signal impending failure. Additionally, electrical safety is critical—always ensure connections are secure, and inspect wires for damage or corrosion. Properly understanding how your pump operates helps you recognize potential problems early, preventing costly repairs. Familiarize yourself with the pump’s components, such as the motor, pressure switches, and control panels. Regularly monitoring pump noise levels and maintaining electrical safety protocols keeps your system running smoothly. Awareness of digital literacy is also important, as it enables you to use diagnostic tools or online resources for troubleshooting. Developing problem-solving skills can further assist in diagnosing and addressing issues promptly. Knowledge of these fundamentals, including automation technologies, empowers you to troubleshoot effectively and ensure your booster pump functions efficiently and safely.

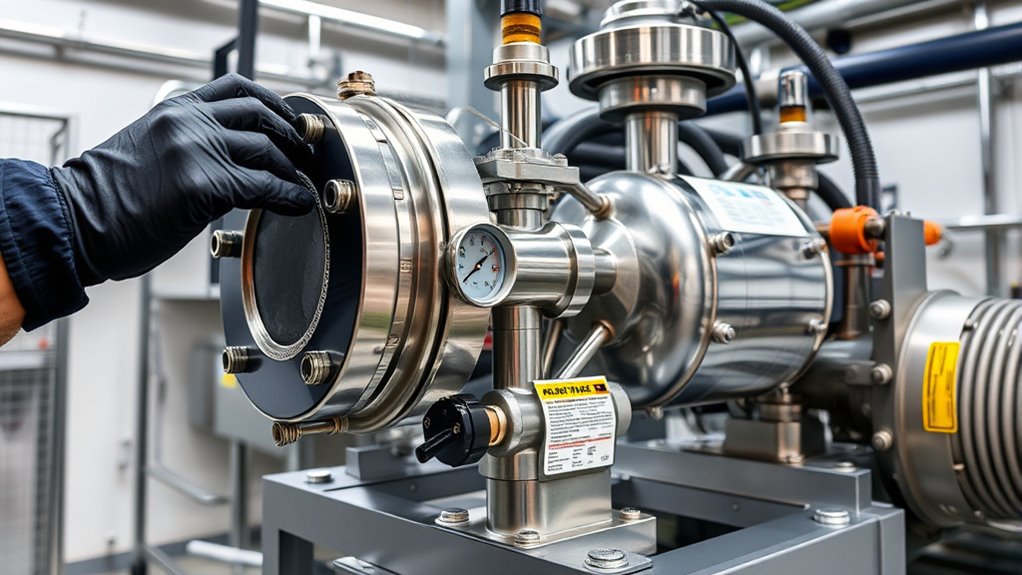

Regular Inspection and Visual Checks

Regular inspection and visual checks are essential to keeping your booster pump operating reliably. You should listen for unusual pump noise, which can indicate problems like cavitation or bearing wear. Check for leaks around fittings and seals, as these can cause damage if left unaddressed. Inspect the electrical wiring for signs of wear, corrosion, or loose connections—faulty wiring can lead to electrical failures or safety hazards. Ensure that wires are properly secured and insulated. Look for any discoloration or burning smells that may point to overheating. Additionally, monitoring pump performance metrics can help you identify early signs of issues before they become serious. Regularly cleaning the pump and surrounding area prevents dust and debris buildup. Performing these visual checks consistently helps you catch minor issues early, reducing downtime and extending your booster pump’s lifespan. Incorporating preventive maintenance strategies can further enhance the reliability and longevity of your equipment. Staying informed about AI safety measures, such as continuous monitoring and safety protocols, can also support the reliable operation of your systems. Understanding the cycle of breakdowns and how to prevent recurring issues can improve your maintenance effectiveness.

Monitoring Water Pressure and Flow Rates

Have you checked the water pressure and flow rates lately? Monitoring these helps confirm your booster pump operates efficiently. Sudden drops in flow or pressure can signal issues like water quality problems or pipe corrosion. Regular maintenance is essential for identifying early signs of system deterioration. Consistent pressure indicates your system is functioning properly, while fluctuations may point to blockages or leaks. Use a pressure gauge to track readings regularly, and compare them to your system’s specifications. If you notice low pressure or inconsistent flow, inspect for signs of pipe corrosion, such as discoloration or buildup. Maintaining proper water pressure not only improves water delivery but also prolongs your pump’s life by preventing strain on its components. Regular monitoring allows you to catch potential problems early, saving you time and costly repairs down the road. Additionally, understanding flow rate dynamics can help optimize your system’s overall performance and efficiency. Being aware of lifecycle factors can provide further insight into when maintenance or upgrades might be necessary to keep your system running smoothly. Incorporating Volkswagen Tuning principles, such as optimizing system performance, can serve as a useful analogy for maintaining your booster pump effectively.

Cleaning the Pump and Its Components

To keep your booster pump running smoothly, it’s vital to clean its components regularly. Start by disconnecting the power supply and carefully disassembling the pump. During pump disassembly, remove parts such as the impeller, casing, and any accessible valves. Cleaning components involves scrubbing away mineral deposits, dirt, and debris that can hinder performance. Use a soft brush and mild cleaning solution to avoid damaging delicate parts. Pay special attention to areas where buildup occurs, like the impeller blades and casing interior. Once cleaned, rinse thoroughly and verify all parts are dry before reassembling. Proper cleaning of components prevents corrosion, reduces wear, and maintains peak flow rates. Regular maintenance like this extends your pump’s lifespan and guarantees reliable operation. Additionally, inspecting for any signs of corrosion or damage during cleaning can help prevent unexpected failures. Incorporating routine maintenance checks can further enhance the longevity and efficiency of your booster pump. Regularly checking for wear and tear ensures that any issues are addressed promptly, maintaining optimal performance.

Checking and Replacing Filters

Regularly check your filters to prevent clogging and maintain ideal flow. Be sure to follow the recommended inspection frequency to catch issues early. When it’s time to replace a filter, do so properly to ensure your booster pump keeps running efficiently. Additionally, understanding filter types can help you choose the best replacements for your system’s needs and optimize its performance. Incorporating knowledge about filter maintenance can extend the lifespan of your pump and improve overall system reliability. Recognizing the benefits of proper filtration can also contribute to better system efficiency and longevity.

Filter Inspection Frequency

Since filters can quickly become clogged with debris and impurities, inspecting them regularly is essential to maintaining your booster pump’s efficiency. Regular checks help you stay ahead of filter lifespan issues and guarantee ideal contaminant removal. How often you inspect depends on your water quality and usage, but a good rule of thumb is to check every 1 to 3 months. Keep an eye out for:

- Visible dirt or buildup that can hinder flow

- Reduced water pressure indicating clogging

- Signs of wear or damage affecting filter performance

- Filtration effectiveness, which may decline if filters are not properly maintained or replaced when needed. Monitoring the cost and budgeting involved in filter replacement can help you plan for future expenses and ensure continuous operation. Additionally, choosing filters with HEPA filtration or other advanced technologies can improve overall removal efficiency. Regularly assessing filter lifespan ensures you replace filters promptly and maintain optimal water quality. Incorporating automated monitoring systems can further optimize maintenance schedules and detect issues early.

Replacing Filter Properly

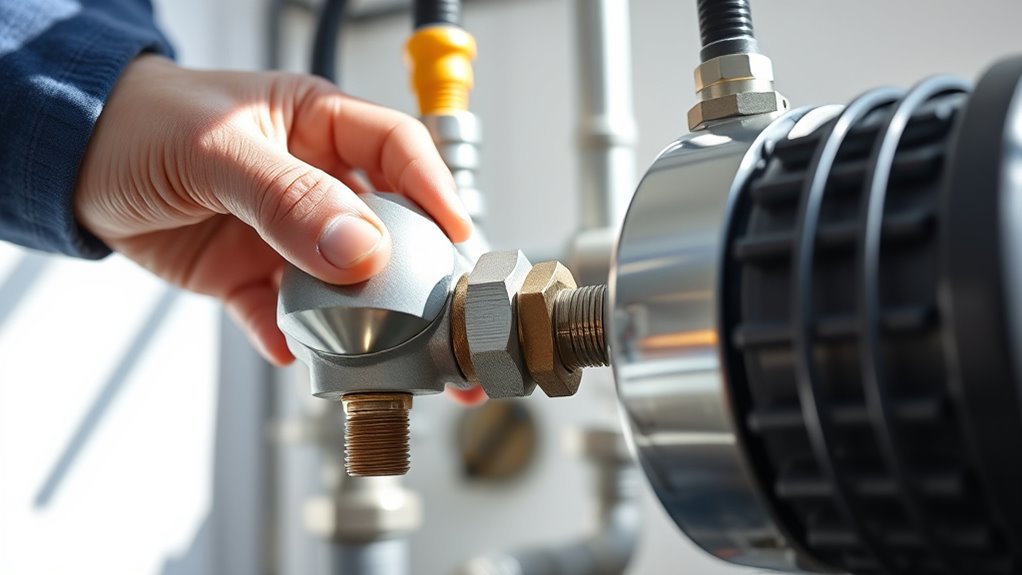

After inspecting your filters and identifying that they need replacement, it’s important to do so properly to maintain your booster pump’s performance. Proper filter replacement ensures your system operates efficiently and prevents damage. Start by turning off the pump and relieving system pressure. Carefully remove the old filter, noting its position for correct installation of the new one. Clean the filter housing to prevent debris buildup. When installing the new filter, make sure it fits snugly and aligns correctly. Follow the manufacturer’s instructions for the specific filter type. Regular filter maintenance is essential for maximum pump function and longevity. Never neglect filter replacement, as dirty or clogged filters can reduce flow rate and strain your pump. Maintaining filters is crucial for the longevity of your booster pump and can prevent costly repairs. Consistent filter maintenance keeps your system running smoothly and extends its lifespan.

Lubricating Moving Parts

To keep your booster pump running smoothly, you need to choose the right lubricant for its moving parts. Following a regular lubrication schedule ensures these parts stay well-oiled and less prone to wear. By staying consistent, you’ll extend the lifespan of your pump and maintain ideal performance.

Selecting Appropriate Lubricant

Choosing the right lubricant is essential for guaranteeing your booster pump operates smoothly and reliably. Proper oil selection not only reduces wear but also prevents overheating and corrosion. To do this effectively, consider the following:

- Ensure lubricant compatibility with pump materials and seals to avoid leaks or damage.

- Choose oils that match the manufacturer’s specifications for viscosity and type.

- Avoid using generic or incompatible lubricants that could cause malfunctions or degrade components.

Regular Lubrication Schedule

Maintaining a regular lubrication schedule for your booster pump’s moving parts helps guarantee smooth operation and prolongs component life. Proper lubrication reduces pump noise and minimizes vibration, which can indicate underlying issues. Regularly check lubrication points as recommended by the manufacturer, and use the appropriate lubricant to prevent friction and wear. Keep an eye on vibration analysis reports; increased vibrations often signal insufficient lubrication or worn parts. Consistent lubrication ensures that bearings and shafts move smoothly, reducing strain on other components. By sticking to a routine, you can catch potential problems early, avoid costly repairs, and keep your booster pump running efficiently. Remember, well-lubricated parts are key to minimizing downtime and extending the lifespan of your equipment.

Testing the Pressure Switch and Valves

Before you start testing the pressure switch and valves, make certain the pump is turned off and unplugged to prevent any electrical hazards. This is essential for safe pressure switch testing and valve inspection. Once safe, check the pressure switch by listening for clicks as you manually adjust the pressure. Also, verify the switch’s connections for corrosion or loose wires. For the valves, inspect for leaks, corrosion, or blockages that could affect performance.

Always turn off and unplug the pump before testing pressure switches and inspecting valves.

Here are key steps to follow:

- Listen for the pressure switch to click when adjusting pressure

- Confirm wiring is secure during pressure switch testing

- Examine valves for leaks or buildup during valve inspection

Troubleshooting Common Pump Issues

When your booster pump isn’t functioning properly, troubleshooting quickly becomes essential to identify and resolve the issue. Common problems include unusual pump noise and vibration issues, which can indicate underlying problems. If the pump makes loud noises, check for debris or loose components. Vibration issues might result from misaligned parts or unbalanced impellers. Use this quick reference to guide your troubleshooting:

| Issue | Possible Cause |

|---|---|

| Excessive Pump Noise | Loose parts, debris, worn bearings |

| Vibration Issues | Misalignment, unbalanced impellers |

| Noisy Operation | Air trapped, motor problems |

Address these issues systematically to restore proper function, ensuring your booster pump runs smoothly and efficiently.

Scheduling Professional Maintenance

If troubleshooting common pump issues hasn’t resolved your booster pump problems, scheduling professional maintenance can prevent future breakdowns and extend the equipment’s lifespan. A trained technician can perform thorough inspections, guarantee proper pump installation, and recommend system upgrades to optimize performance. Regular professional check-ups catch small issues before they turn into costly repairs. During maintenance, you might:

- Update or upgrade your system for better efficiency

- Make certain all connections and components are secure and functioning correctly

- Receive expert advice on future pump installation and upgrades

Frequently Asked Questions

How Often Should I Schedule Professional Maintenance for My Booster Pump?

You should schedule professional maintenance for your booster pump at least once a year. Regular scheduled inspections help identify wear and tear early. During these visits, professionals can perform component upgrades if needed, ensuring peak performance. If your pump experiences heavy use or operates in harsh conditions, consider more frequent checkups. Staying proactive with maintenance keeps your booster pump running efficiently and extends its lifespan, preventing costly repairs down the line.

What Are Signs That My Booster Pump Needs Immediate Repair?

Imagine your booster pump working smoothly, then suddenly, it groans or stalls. If you notice troubleshooting leaks or the pressure gauges fluctuating unexpectedly, it’s a sign you need immediate repair. Unusual noises, persistent leaks, or pressure drops indicate problems. Don’t ignore these signs—they could point to a failing pump. Address issues promptly to prevent further damage, ensuring your system stays reliable and efficient.

Can I Upgrade Components to Improve Pump Efficiency?

You can definitely upgrade components to boost your booster pump’s efficiency. Consider replacing outdated parts like the motor, impeller, or seals with modern, high-efficiency alternatives. These component upgrades can lead to significant efficiency improvements, saving energy and reducing wear. Before making any changes, check compatibility and consult a professional to guarantee the upgrades align with your system’s needs, maximizing performance and longevity.

How Do Environmental Factors Affect Booster Pump Performance?

Environmental factors greatly influence booster pump performance. Harsh conditions, like extreme temperatures, humidity, or exposure to chemicals, can reduce pump durability and cause wear. Dust and debris can clog components, leading to inefficiency. To guarantee ideal operation, you should monitor environmental impact regularly, protect the pump from adverse elements, and perform routine maintenance. This proactive approach helps maintain pump durability and prevents unexpected breakdowns, keeping your system running smoothly.

Are There Safety Precautions to Consider During Maintenance?

When performing maintenance, you should prioritize safety precautions. Always wear personal protective equipment like gloves and eye protection to prevent injuries. Guarantee electrical safety by disconnecting power before working on the pump to avoid shocks. Follow proper procedures and use insulated tools when handling electrical components. Staying alert and cautious minimizes risks, helping you maintain the booster pump safely and effectively.

Conclusion

With regular maintenance, your booster pump runs smoothly like a well-oiled machine, quietly working behind the scenes to keep your water pressure steady. Imagine the gentle hum of the pump as it powers through, its components clean and functioning perfectly. By staying proactive, you guarantee this essential system continues to serve you reliably, preventing unexpected breakdowns. Keep your pump in top shape, and enjoy the steady flow of water flowing effortlessly through your home.