To care for your pressure pool cleaner during the off-season, disconnect it from power and the pool, then thoroughly clean and rinse all parts. Inspect hoses, brushes, and seals for damage, replacing worn components. Lubricate moving parts and store the unit in a cool, dry place away from extreme temperatures. Proper storage and maintenance help keep your cleaner in top shape for next season—continue to learn more about ensuring your equipment’s longevity.

Key Takeaways

- Disconnect the cleaner from power and skimmer lines, then clean and dry all parts before storage.

- Inspect hoses, brushes, and seals for damage, cracks, or wear, replacing any worn components.

- Check for leaks or water escaping, tighten fittings, and seal any cracks to prevent damage.

- Lubricate moving parts and store the cleaner in a cool, dry, sheltered environment away from weather.

- Prepare for next season by cleaning thoroughly, adjusting pool chemistry, and ensuring all parts are in good condition.

Disconnecting and Cleaning the Pressure Pool Cleaner

When it’s time to store your pressure pool cleaner for the off-season, start by disconnecting it from the pool’s skimmer or dedicated line. Before cleaning, check the pool water chemistry to make certain the water’s balanced; this helps prevent mineral buildup inside the equipment. Rinse the cleaner thoroughly with a hose to remove dirt, debris, and any residual chemicals. Pay special attention to the brushes and hoses, removing any clogs or buildup. While cleaning, follow pool safety tips by wearing gloves and eye protection. Properly draining and drying the cleaner helps prevent mold and corrosion during storage. Additionally, understanding water chemistry can help you better maintain your pool and equipment. Ensuring the proper equipment storage conditions can extend the lifespan of your pressure pool cleaner and keep it in optimal working order. Regularly inspecting and maintaining pool accessories before storage can prevent issues when reusing them next season. Incorporating remote work productivity techniques such as setting clear routines can also help in managing maintenance tasks efficiently. Being aware of AI safety measures and proper handling protocols can also prevent accidents and equipment damage. Taking these steps guarantees your pressure pool cleaner remains in good condition, ready for a smooth restart next season, and helps maintain safe pool water chemistry throughout the process.

Inspecting for Wear and Damage

You should carefully inspect your pressure pool cleaner for any visible damage or cracks. Check for leaks around joints and seals that could cause issues later. Also, examine wear points like brushes and wheels to make sure they’re still in good condition. Additionally, verify that paint sprayer accessories such as nozzles and strainers are clean and free of clogs to ensure optimal performance during your next use. Regular maintenance can help prevent equipment failure and extend the lifespan of your pressure pool cleaner. Taking time to perform these checks can also identify any regional issues that might affect equipment longevity. For example, environmental factors like climate conditions can accelerate wear and require more frequent inspections, ensuring your equipment remains reliable. Ensuring your self-watering plant pots are functioning properly can serve as a helpful analogy for maintaining your pool equipment effectively.

Visual Damage Inspection

Regularly inspecting your pressure pool cleaner for visible signs of wear and damage is essential to keep it functioning effectively. Focus on a surface assessment to spot issues early. Perform a thorough visual inspection, checking for cracks, tears, or worn spots on hoses, brushes, and seals. Look for areas where the material appears brittle or discolored. Also, examine the connection points to ensure they’re secure and free of debris. Regular checks help identify potential issues before they lead to bigger problems. Incorporating preventive maintenance into your routine can further extend the lifespan of your equipment. For example, inspecting the internal components for corrosion or mineral buildup can prevent performance degradation. Additionally, verifying connection points and fittings ensures proper operation and minimizes leaks. Imagine seeing frayed edges on the hose, a cracked brush, or missing clips. These visual cues signal it’s time for maintenance or replacement. Keeping a close eye on these details helps prevent breakdowns and maintains optimal cleaning performance during the season’s off months, especially when off-season care is a priority.

Check for Leaks

Leaks can silently undermine your pressure pool cleaner’s efficiency, so it’s important to check for any signs of water escaping from hoses, seals, or connection points. Leak detection starts with a visual inspection—look for damp spots, water drips, or puddles around the unit. Pay close attention to connections and seals, as these are common leak sources. If you notice a leak, use sealing techniques such as tightening fittings or applying waterproof sealant to ensure a tight fit. Regularly inspecting for leaks helps prevent water loss and maintains ideal cleaning performance. Proper filtration systems can also help prevent debris buildup that might cause leaks or damage. Additionally, inspecting and maintaining seals and gaskets can prevent leaks and extend the lifespan of your cleaner. Addressing leaks early also extends the lifespan of your pressure pool cleaner and saves you money on repairs during the off-season. Stay vigilant, and your cleaner will be ready when the season starts again.

Examine Wear Points

After checking for leaks, it’s important to examine the pressure pool cleaner’s wear points. These are areas prone to damage, especially impact zones that endure constant contact with rough surfaces or debris. Look for cracks, tears, or thinning in the hoses, brushes, and seals. Pay close attention to the impact zones where the cleaner hits the pool walls or floor repeatedly. These spots often show signs of wear before other parts. Regularly inspecting wear and tear and replacement parts can help maintain optimal performance and extend the lifespan of your cleaner. Inspecting these wear points helps prevent costly repairs and ensures your cleaner functions properly when you restart it.

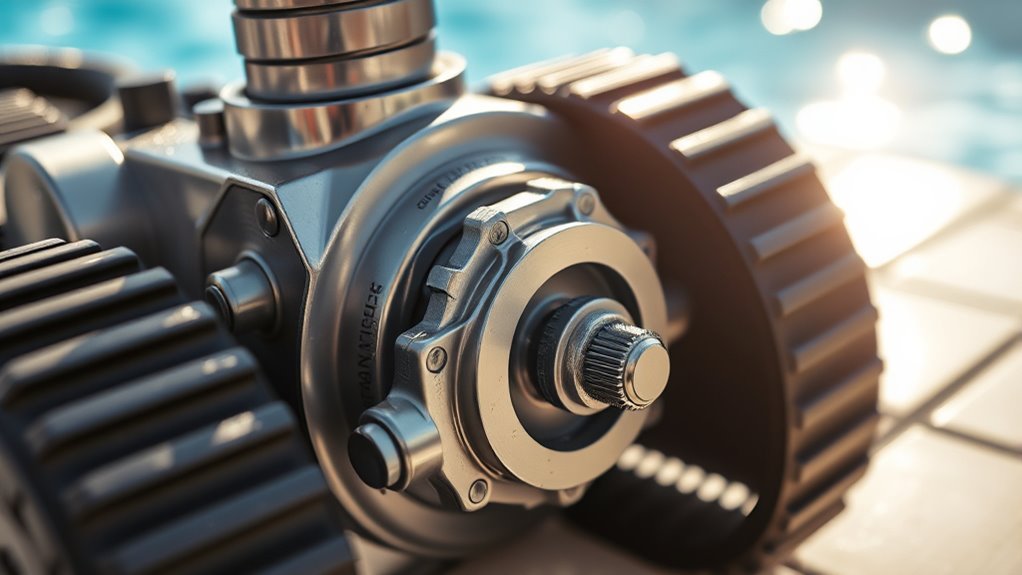

Lubricating Moving Parts

Make sure you use the right lubricants designed for your pressure pool cleaner’s parts to keep everything running smoothly. Regularly check the moving components for signs of dryness or stiffness, and apply lubricant as needed. Proper lubrication helps prevent wear and extends the lifespan of your cleaner. Incorporating preventive maintenance routines can further ensure your equipment operates efficiently during the off-season, especially by maintaining optimal air purifier performance to reduce dust and debris buildup. Additionally, using lubricants that are compatible with outdoor equipment can help withstand environmental exposure and prolong the effectiveness of your maintenance efforts.

Use Appropriate Lubricants

To guarantee your pressure pool cleaner operates smoothly during the off-season, using the right lubricants on its moving parts is essential. Choose appropriate lubricant types designed for pool equipment to prevent rust and ensure seamless operation. When applying, follow proper application techniques: clean parts first, apply sparingly, and avoid over-lubricating. Visualize the process as you:

- Gently spread lubricant along the gear shafts and hinges

- Carefully wipe away excess to prevent dirt buildup

- Focus on areas prone to friction to reduce wear

- Regular maintenance, including inspection for leaks, can further prolong component life

Using the correct lubricant types and applying them properly helps maintain your cleaner’s functionality and extends its lifespan. This simple step keeps the components moving effortlessly, ready for trouble-free operation when you reopen the pool. Additionally, understanding automation in business can help you explore how technological advancements improve maintenance efficiency.

Regularly Check Moving Parts

Regularly inspecting your pressure pool cleaner’s moving parts guarantees they stay in good condition and function smoothly. During off-season storage, focus on lubrication tips to prevent rust and wear. Apply a suitable lubricant to gears, bearings, and joints to keep everything operating seamlessly. Check for signs of corrosion or stiffness, and address them promptly. Proper storage solutions also play an essential role; store your cleaner in a dry, cool place to minimize exposure to moisture and temperature fluctuations. Before storing, clean and dry all parts thoroughly to avoid corrosion. Regular checkups ensure your pressure pool cleaner remains ready for use when the season resumes, saving you time and money later. Keep moving parts well-lubricated and stored correctly to extend your cleaner’s lifespan.

Removing and Storing Hoses and Cables

When the swimming season ends, removing and storing hoses and cables properly guarantees your pressure pool cleaner stays in good condition. Start by disconnecting hoses and cables from the cleaner and pool equipment. Next, coil the hoses carefully to prevent kinks and damage, using hose organization techniques like loose loops or hose reels. For cables, practice cable management by winding them neatly, avoiding tight bends that could cause cracks.

Visualize:

- Gently rolling hoses into loose coils, avoiding twists or knots

- Securing cables with velcro straps or clips to keep them tidy

- Storing hoses and cables in a dry, protected area to prevent deterioration

Proper removal and storage protect your equipment and ensure easy setup for next season.

Proper Storage Locations and Conditions

Choosing the right storage location and maintaining proper conditions help guarantee your pressure pool cleaner remains in top shape for next season. Ideally, store it in a garage where temperature and humidity are controlled. Avoid exposing it to extreme heat, cold, or moisture, which can damage components. Climate considerations are critical; a dry, cool environment prevents mold and corrosion. Ensure the cleaner is stored in a dry place away from direct sunlight. Use a shelf or secure storage bin to keep it safe from accidental damage. Consider the following storage tips:

| Location | Climate Considerations | Storage Tips |

|---|---|---|

| Garage | Controlled temperature | Keep off the floor, dry shelf |

| Basement | Moisture risks | Use sealed containers |

| Shed | Fluctuating temperatures | Avoid direct sunlight |

| Closet | Humidity control | Keep in a breathable bag |

| Exterior storage | Extreme weather exposure | Not recommended |

Checking and Replacing Worn Components

Inspecting your pressure pool cleaner for worn components is essential before storing it for the season. Conduct a thorough wear assessment to identify parts that may need component replacements. Look for cracks, tears, or brittleness in hoses and seals. Check the brushes and wheels for excessive wear or damage. Examine the fan blades for chips or warping, and inspect the drive belt for fraying or slack. Visualize the process:

- Running your fingers along hoses to feel for cracks or stiffness

- Holding brushes up to the light to spot worn bristles or breaks

- Rotating wheels and fan blades to detect wobbling or deformation

Addressing these issues ensures your cleaner remains in top shape. Replacing worn components now prevents bigger problems during the next season and guarantees bestperformance when you resume cleaning.

Maintaining the Filtration System and Nozzles

Maintaining your pressure pool’s filtration system and nozzles is essential to guarantee peak cleaning performance during the season’s end. Regular filtration maintenance ensures debris doesn’t clog your system, while nozzle calibration keeps water flow optimized. To help visualize, here’s a simple overview:

| Filtration Maintenance | Nozzle Calibration |

|---|---|

| Clean or replace filters regularly | Adjust nozzles for even spray |

| Remove debris from skimmers | Check nozzle angles for efficiency |

| Backwash when needed | Ensure no leaks or blockages |

| Maintain clean pump baskets | Test water pressure consistency |

| Inspect seals and gaskets | Replace worn or damaged nozzles |

Preparing Your Cleaner for the Next Season

As the swimming season winds down, it’s important to prepare your pressure pool cleaner for storage and the months ahead. Proper preparation guarantees it stays in good condition and ready for next season. Start by checking the pool chemistry, adjusting chemicals to proper levels to prevent algae or corrosion. Clean the cleaner thoroughly, removing debris and rinsing off any dirt or grime. Follow safety precautions by disconnecting it from power sources and storing it in a dry, sheltered area. To prevent damage, consider lubricating moving parts and inspecting hoses for cracks or wear. Visualize your cleaner sitting safely on a shelf, surrounded by pool accessories, ready for the off-season. Properly prepared, your cleaner will be primed for effortless use when spring arrives.

Frequently Asked Questions

How Often Should I Perform Off-Season Maintenance on My Pressure Pool Cleaner?

You should perform off-season maintenance on your pressure pool cleaner at least once a year. Follow winterizing tips to properly prepare it for storage, and verify you clean and inspect all parts. Storage best practices include draining water, removing hoses, and storing in a dry, sheltered place. Regularly check your cleaner during the off-season for any damage, so it’s ready to go when swimming season resumes.

Can I Store My Pressure Pool Cleaner Outdoors During Winter?

Did you know that outdoor storage can expose your pressure pool cleaner to damage? While it might seem convenient, storing it outdoors during winter isn’t ideal. You should always provide winter protection by keeping your cleaner in a dry, sheltered spot, or ideally indoors. This prevents freezing, rust, and damage from harsh weather. Protect your investment by opting for indoor storage or outdoor shelter during cold months.

What Are Signs That My Pressure Pool Cleaner Needs Replacement Parts?

If you notice your pressure pool cleaner isn’t performing well, look for replacement indicators like reduced suction, inconsistent cleaning, or strange noises. These signs often point to component wear or damage. You might need to replace parts such as the hoses, brushes, or the motor. Regular inspection helps identify these issues early, ensuring your cleaner works efficiently and prolongs its lifespan. Always follow manufacturer guidelines for timely replacements.

Is It Necessary to Rinse the Cleaner After Each Use Before Storage?

You might wonder if rinsing your pressure pool cleaner after each use is necessary before storage. Regular cleaning frequency helps prevent buildup and prolongs its lifespan. Rinsing thoroughly removes debris, chemicals, and dirt, which can cause damage over time. For storage tips, make sure it’s completely dry and stored in a cool, dry place. This simple step keeps your cleaner in good condition and ready for the next pool season.

How Do Temperature Changes Affect the Longevity of Pressure Pool Cleaner Components?

Temperature fluctuations can impact the component durability of your pressure pool cleaner. When temperatures vary widely, it causes expansion and contraction of parts, which may lead to cracks or wear over time. To protect your cleaner’s longevity, avoid exposing it to extreme temperature changes and store it in a stable environment. Proper care helps maintain the integrity of components, ensuring your pressure cleaner performs efficiently season after season.

Conclusion

By giving your pressure pool cleaner proper off-season care, you’re fundamentally planting the seeds for a smooth start next season. Regular cleaning, inspection, and smart storage keep it in top shape, ready to dive back into action. Think of your maintenance routine as tending a garden—you’ll reap the rewards of a cleaner, healthier pool with less hassle. With a little effort now, you’ll ensure your pool stays sparkling and your cleaner lasts for many seasons to come.